Year of implementation: 2023-2024

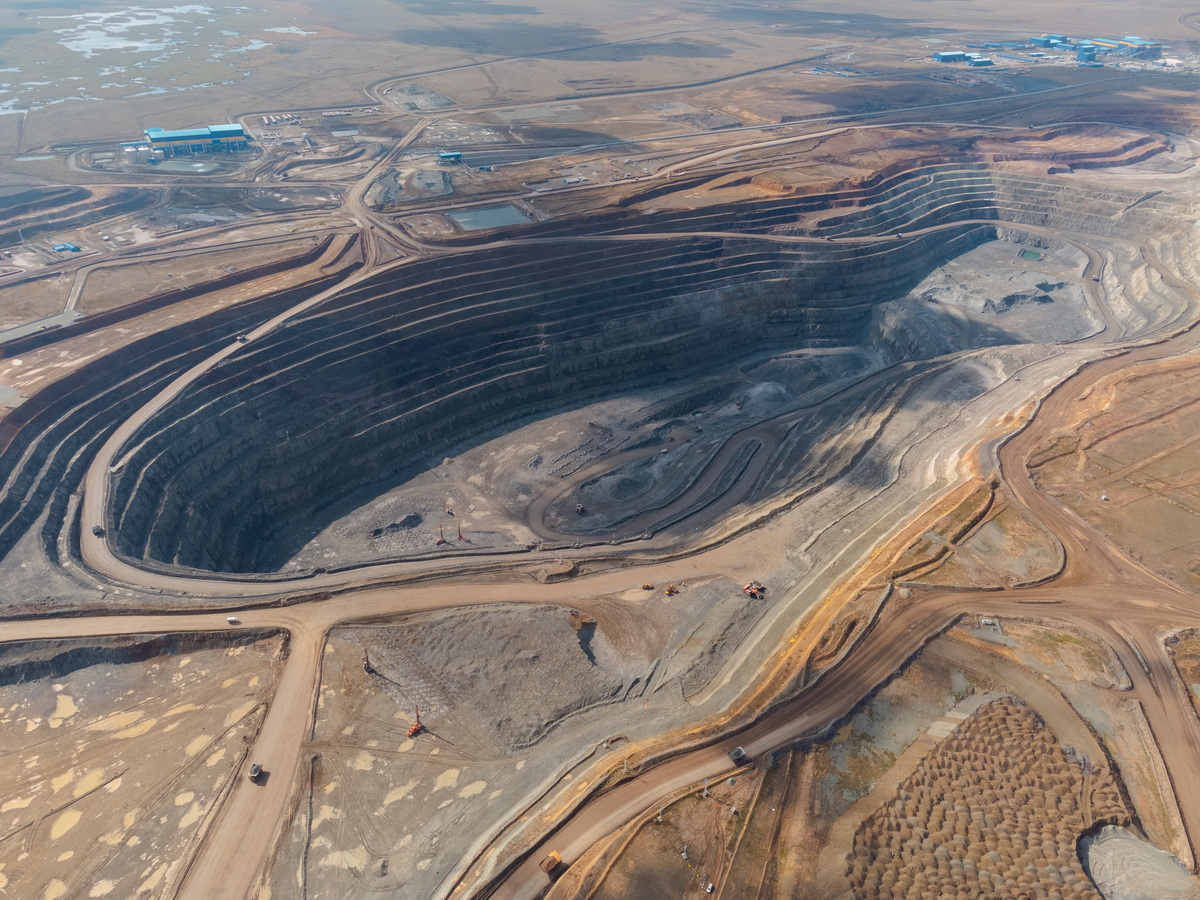

Location: Bozshakol deposit, Pavlodar region, Republic of Kazakhstan.

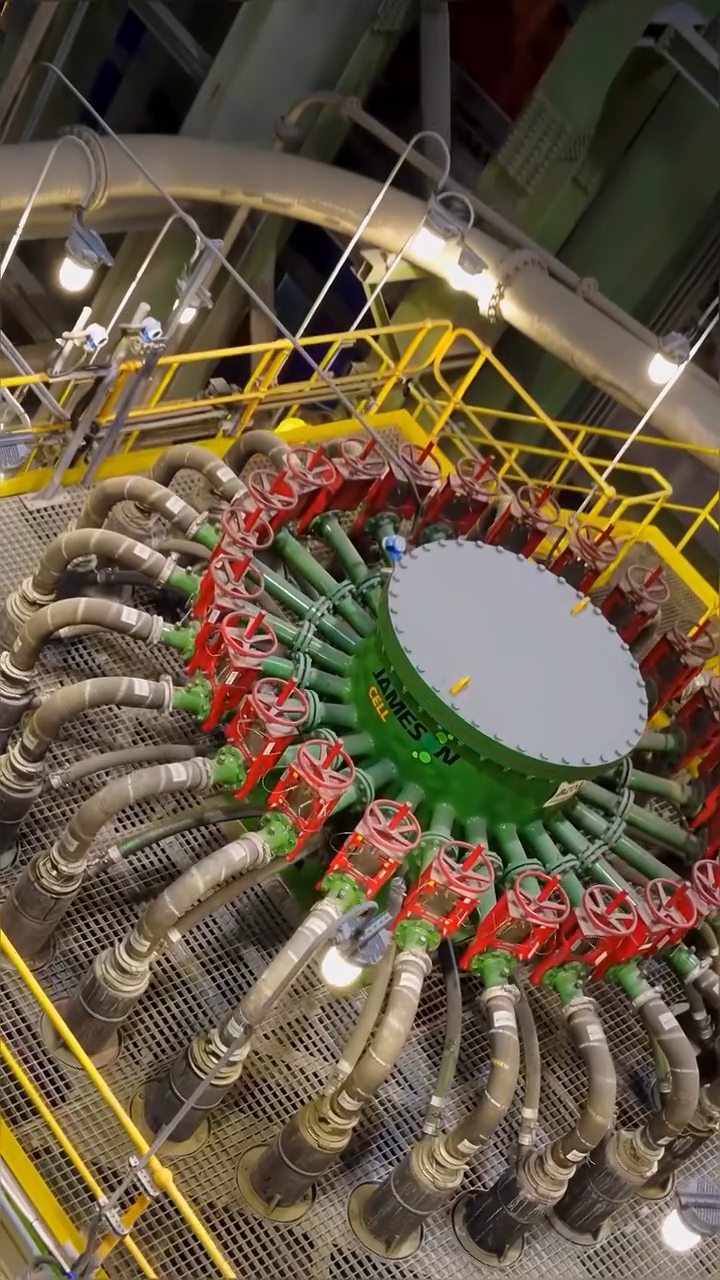

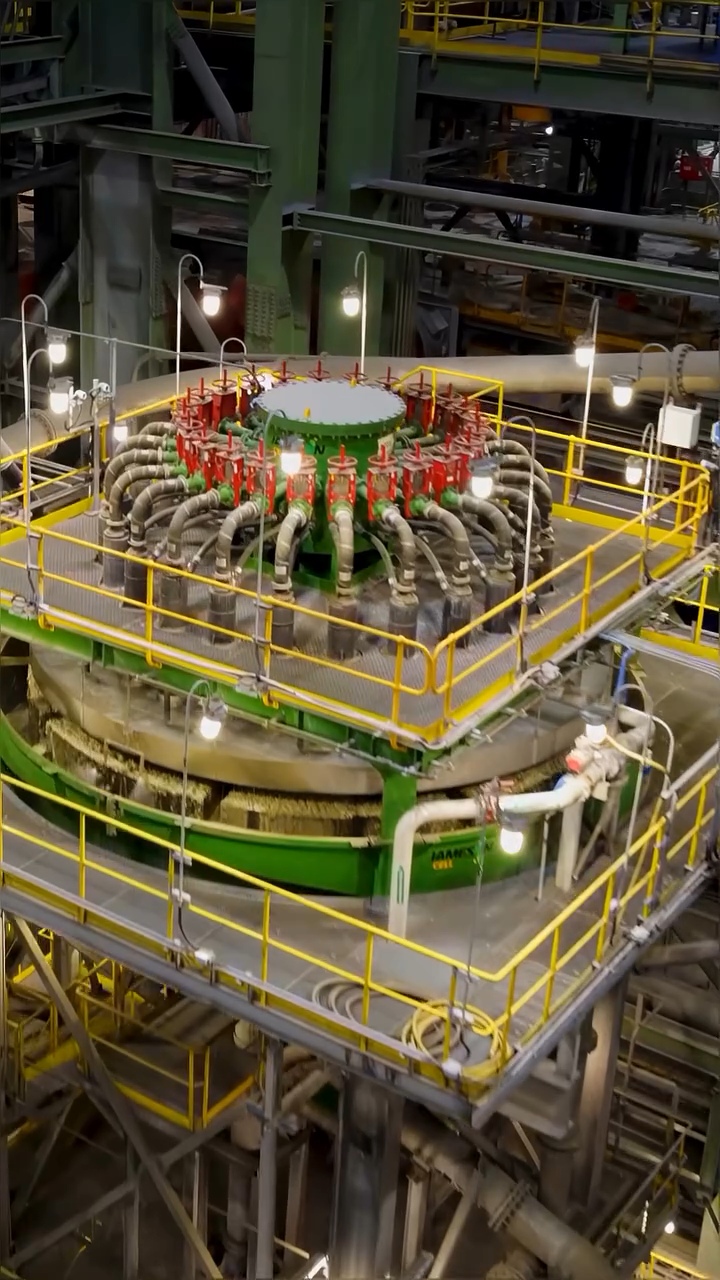

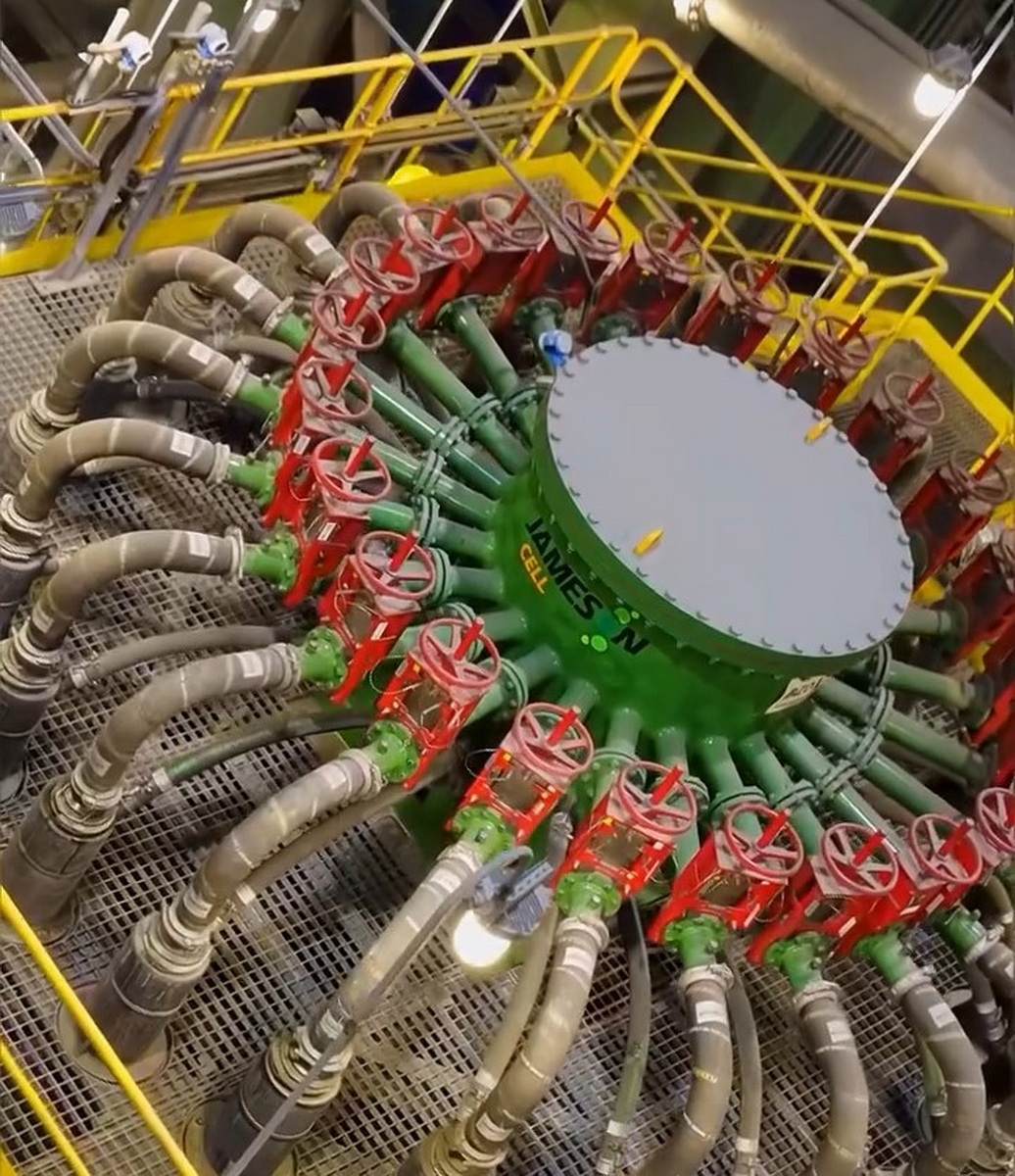

Brief description of the facility: Installation of a Jameson B6500/24 flotation cell, manufactured by Glencore Technology Pty Ltd, in the cleaning flotation section of the existing building of the Bozshakol Sulphide Concentrator of the KAZ Minerals Group. The territory of the existing construction site is an industrial building with utility networks.

Project objective: Increasing the recovery and quality of the final concentrate by redirecting the flows of re-crushed or under-crushed rough concentrates from the rough flotation to the Jameson flotation cell, as well as distributing the resulting concentrate and tailings according to the further process flow.

Feature: The advantage of the Jameson flotation cell is its proven technology with easy adjustment of flotation process variables in automated control loops. Another advantage is the absence of the need to supply additional compressed air to the flotation cell.

Our designers have developed a Detail Design, including:

Installation of a Jameson fleet machine, feed tanks and tailings with corresponding centrifugal pulp pumps equipped with a variable frequency drive (VFD);

Installation of ultrasonic level sensors;

Installation of automatic samplers and separate pipelines for concentrate and tailings samples;

Modification of the first cleaning tailings pump to increase its capacity to 3500 m³/hour.

In addition, we have carried out:

Project examination for compliance with industrial safety requirements.

Environmental assessment of the project.

3D scanning of the site selected for installation of the Jameson Cell and auxiliary equipment.

Participation in public hearings on the project in accordance with the requirements of the Environmental Legislation of the Republic of Kazakhstan.

Participation in the comprehensive non-departmental examination.

Author's supervision during the production process.